Metal additive manufacturing has evolved rapidly over the past decade, and 2026 is shaping up to be the most promising year yet for businesses looking to invest in a metal 3D printer. Industries across aerospace, automotive, energy, research, and medical manufacturing are shifting from traditional machining to metal 3D printing because it saves time, reduces waste, and enables designs that were previously impossible to create. As technology advances and equipment becomes more accessible, more companies realize that 2026 is the ideal time to make the move toward metal additive manufacturing.

Whether you’re running a small fabrication shop or managing a high-volume production facility, metal 3D printing provides accuracy, durability, and flexibility. With better machines, improved materials, and lower operating costs, the timing has never been better to explore this high-value technology.

Demand for Precision Parts Is Growing

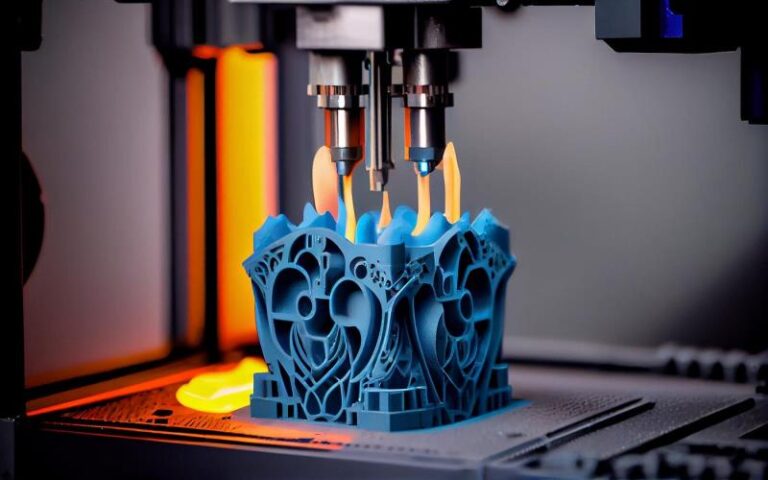

One of the biggest reasons 2026 stands out is the rise in demand for lightweight, precise, and high-performance metal components. Industries that once relied completely on machining or casting now use additive manufacturing to improve speed and efficiency. Because many companies need faster production without compromising strength, technologies like the DMLS 3d printer and SLM 3d printer are becoming essential.

These printers produce fully dense metal parts with excellent mechanical properties. They allow manufacturers to create internal channels, lattice structures, and complex shapes that traditional cutting tools cannot achieve. As a result, metal 3D printing is helping businesses innovate faster and bring new products to market with greater confidence.

Lower Costs and Better Technology in 2026

The cost of Metal 3D Printing has dropped significantly. Machines are now faster, more energy-efficient, and easier to operate. Software improvements, automated calibration, and advanced monitoring tools allow even small businesses to benefit from metal additive manufacturing.

Key advancements include:

- Higher printing speeds

- Better accuracy

- Improved powder handling

- Smarter sensors and real-time monitoring

- Lower maintenance requirements

As a result, many companies that relied solely on a metal 3d printing service are now considering in-house printers. Although outsourcing still works for large or complex jobs, owning a machine gives businesses more freedom, speed, and long-term savings. With material suppliers like ACS Material offering reliable metal powders, it is easier than ever to maintain consistent print quality.

Greater Control Over Production Timelines

One of the biggest advantages of having an in-house Metal 3D Printer is full control over your production cycle. Instead of waiting days or weeks for an external provider to deliver parts, you can produce components immediately when needed. This flexibility becomes a major advantage during urgent projects or rapid prototyping phases.

Companies that once depended on a 3d metal printing service now prefer hybrid workflows. They outsource large or complex builds but print smaller or urgent parts in-house. This balance helps them stay efficient while managing costs more effectively.

Better Material Options and Stronger Parts

In previous years, metal 3D printing was limited to a few materials. Now, in 2026, you can print with:

- Stainless steel

- Titanium

- Inconel

- Tool steel

- Aluminum alloys

- Cobalt chrome

These materials help create parts that match or outperform machined components. The quality of printed metal has improved significantly. The parts are stronger, smoother, and more reliable than before. Whether you produce aerospace brackets, automotive components, or medical instruments, you can count on consistent performance and durability.

This is especially important for 3d metal printing applications where precision and long-term strength play a major role.

Customization and Rapid Prototyping Become Easier

Customization is becoming crucial across many industries. Customers want specialized designs, lighter components, and improved product features. A metal 3D printer makes it easy to create unique parts without additional tooling. This removes the need for molds, dies, or expensive fixtures.

Rapid prototyping becomes faster because changes can be implemented instantly. Updating a model and printing a new prototype can take hours instead of days. This is a big advantage for design teams who want to test, refine, and finalize concepts quickly.

Reduced Waste and Better Use of Materials

Metal 3D printing uses only the amount of material needed to build a part. Traditional machining often cuts away large sections of metal, producing waste that must be recycled or discarded. With additive manufacturing, material usage is more efficient and environmentally friendly.

This reduction in waste directly lowers production costs. It also allows manufacturers to experiment with expensive materials like titanium or Inconel without worrying about excessive scrap.

Perfect Timing for Small and Large Businesses

2026 is a turning point for both small workshops and large manufacturing plants. Smaller companies benefit because metal 3D printers are more affordable than ever, giving them access to technology that once belonged only to major corporations. Larger companies benefit from improved production speeds, stronger quality control, and the ability to build complex parts in-house.

This means any business—no matter the size—can now explore additive manufacturing with confidence.

Final Thoughts

2026 is the best year to invest in a 3D metal printer because technology has matured, costs have decreased, and industry demand is stronger than ever. Whether you rely on a metal 3d printing service, need better control over production, or want to explore new design possibilities, owning a metal 3D printer gives you a major competitive advantage. Thank visiting youthfulyarn.com