Organizing electrical cables is important in today’s industrial and commercial environments. One of the most effective methods for organizing, supporting, and protecting electrical wiring systems is to fabricate a cable tray and install it properly. A cable tray will protect electrical cable and provide a safe pathway for electrical wires that is functional and maintainable. This guide will discuss the process of cable tray fabrication and installation, and further highlight the considerations of using a GI cable tray for various applications.

Understanding Cable Trays

Cable trays are structural systems designed to support insulated electrical cables used for power distribution, control, and communication. They simplify complex wiring networks, provide accessibility for maintenance, and enhance the overall reliability of electrical systems.

Types of Cable Trays

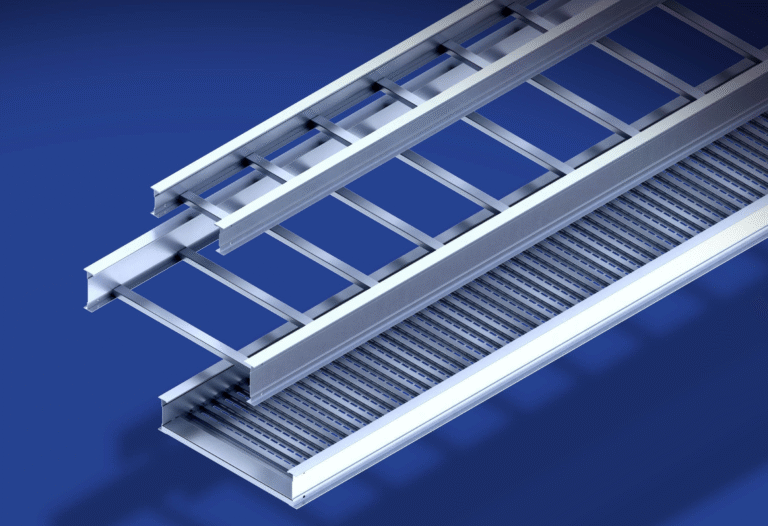

Ladder Type Cable Tray – Consists of two side rails connected with rungs spaced at regular intervals, designed for heavy-duty applications.

Perforated Type Cable Tray – Has holes or perforations for ventilation and heat dissipation; a commonly used tray in commercial environments.

Solid Bottom Cable Tray – Provides full protection from dust and contaminants, suitable for sensitive installs.

Trough Type Cable Tray – Provides medium ventilation and protection for cables, achieving some balance between airflow and safety.

Wire Mesh Cable Tray – Light-weight and easy to install, usually associated with telecommunication or low-voltage cabling systems.

Each tray type is selected according to load capacity, the environment in which it is installed, and the requirements for electrical cable management.

Cable Tray Fabrication Process

The cable tray fabrication process involves multiple stages of design, material selection, cutting, shaping, and finishing to produce durable and corrosion-resistant trays. Precision and quality control are critical to ensure that trays meet international standards for strength and safety.

1. Material Selection

The type of material affects the operation and useful life of the tray. The most common materials are mild steel, stainless steel and aluminum. Among these materials, GI cable trays (Galvanized Iron) are found to be the best choice because they are reasonably priced, reliable and corrosion-resistant. In the galvanization process, the metal is coated in a zinc layer that serves as a barrier to rust. GI cable trays are ideal support systems for indoor or outdoor installations for this reason.

2. Design and Engineering

The design engineer uses a CAD program to produce working drawings of the cable trays, being sure that the dimensions are accurate and compatible with the electrical design. This step also includes the tray’s width, depth, thickness and load bearing design factors.

3. Cutting and Forming

During this phase of fabrication, the metal sheets are cut accurately to sizes used in the design through the CNC process. The individual trays are then subjected to a bending and forming operation to attain the final shape. In the case of cable tray fabrication, accurate bending and welding of the cable trays is very important to ensure the structural integrity of the tray structure.

4. Perforation and Finishing

Depending on the type of design, holes or holes, or slots, are punched during this stage of the process. The holes are used as fastening mechanisms and for ventilation of the cables within the tray. Lastly, after the tray has been completely fabricated, GI trays are typically hot-dipped galvanizing process will provide maximum corrosion protection. There is also an option to powder coat or paint as well, which would provide a durable and appealing finish.

Installation of Cable Trays

Proper installation ensures the safety and efficiency of the electrical cable management system. Each step must comply with industry standards and local electrical codes.

1. Site Preparation

Prior to installation, the layout is designed per the electrical design. Support structures, such as brackets or hangers, are placed periodically to distribute the weight evenly.

2. Mounting and Alignment

Cable trays can be mounted on walls, ceilings, or floors depending on job installation. The trays must be aligned; they must be level and connected to each other to maintain the continuity of the tray, and to avoid sag.

3. Cable Laying

After the trays have been attached, the cables are arranged to be organized in the trays. Providing space between cables is necessary for identification and helps to avoid heat buildup. When managing electrical cables, it is crucial to keep power and data cables separated from each other in order to avoid interference.

4. Earthing and Bonding

To prevent electrical shock and to maximize the system’s reliability, it is critical that all metallic trays are properly grounded.

5. Inspection and Maintenance

After the installation is complete, the entire system is preformed to inspect for mechanical strength, alignment, and grounding integrity. Regular inspections can assist in recognizing any loose fittings or damaged sections.

Advantages of Cable Tray Systems

- Enhanced Organization: Cable tray fabrication offers structured pathways for routing cables, improving overall system aesthetics.

- Flexibility: Trays can be easily modified, extended, or rerouted as system needs evolve.

- Cost-Effectiveness: Compared to conduit systems, GI cable trays are less expensive and easier to install.

- Safety: Cable trays reduce clutter and minimize fire hazards through better air circulation.

- Durability: Galvanized finishes provide long-lasting protection against corrosion and environmental damage.

Importance of GI Cable Trays in Electrical Installations

Cable trays made from galvanized iron are extremely important in industrial environments like manufacturing facilities, refineries, and data centers. Their strong structure and ability to resist corrosion make them attractive for tough environments. Additionally, GI cable tray fabrication ensures consistency, longevity, and maintenance-free operation. Also, cable trays provide a straightforward future extension strategy for running additional cables without major modification.

GI cable trays enhance cable management system but provide better load capacity.

They enable the efficient load-bearing of large cables while maintaing reliability and safety of the system.

Why Choose BrighttechEngineering for Cable Tray Fabrication

BrighttechEngineering is a recognized name in the field of quality cable tray fabrication. The company utilizes advanced machinery, highly skilled professionals, and high-quality raw materials in producing their durable and reliable items. Their experience guarantees that each project complies with international standards and customer-specific specifications.

BrighttechEngineering provides bespoke GI cable trays and related accessories for reliable management of electrical cables. They offer complete end-to-end solutions, from design through installation, to achieve optimal performance and safety in industrial and commercial projects.

In conclusion, understanding cable tray fabrication and proper installation techniques is essential for maintaining an efficient and safe electrical cable management system. Using GI cable trays enhances durability, performance, and long-term cost savings. With expert support from BrighttechEngineering, organizations can ensure their cabling infrastructure is well-organized, reliable, and built to last.