Work at height brings inherent risks. Falls remain one of the leading causes of workplace injuries in construction, industrial maintenance, infrastructure projects, and energy sectors. For businesses that operate in high-risk environments, selecting a fall arrest system supplier is a foundational safety decision.

A supplier does more than deliver equipment. A reliable partner ensures you receive compliant, performance-tested fall protection systems. They support your safety officers, engineering teams, and project managers with clear guidance, timely delivery, and ongoing safety support. Choosing the right supplier means your workers are safer, your compliance risks are reduced, and your project delivery is smoother.

This guide explains how to choose reliable fall arrest system suppliers for your business. It covers criteria that matter for industrial safety, practical evaluation steps, and key questions to ask before you commit to a supplier.

Why Supplier Choice Matters for Fall Protection

Workplaces that require fall protection depend on systems such as:

- Personal fall arrest systems

- Ladder fall arrest systems

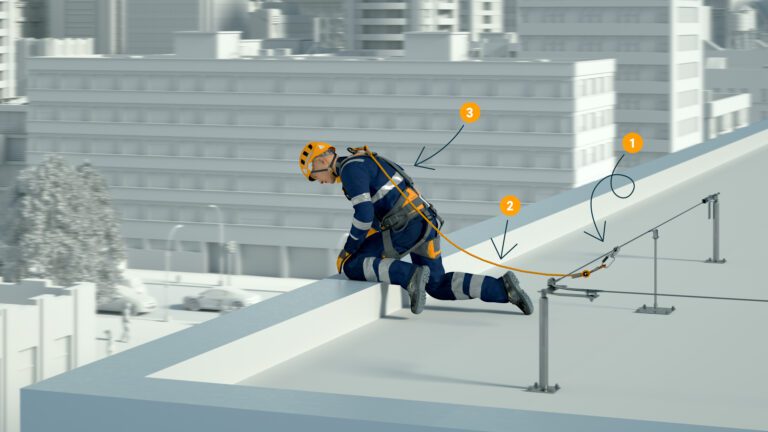

- Roof fall arrest systems

- Horizontal lifeline systems

- Vertical fall arrest systems

- Fall protection systems for industrial sites

The quality and suitability of these systems directly affect worker safety, regulatory compliance, and operational continuity. Poor-quality fall arrest systems can fail under load, introduce hazards, or create false confidence among workers.

A dependable supplier provides systems that meet standards like OSHA, EN, and relevant Indian safety codes. They also offer technical support that helps safety teams install, inspect, and maintain equipment correctly.

1. Verify Certification and Compliance

When evaluating fall arrest system suppliers, compliance should be your first filter.

Key points to verify:

- Product Certifications: Check that fall arrest systems are certified to recognized international and regional standards such as OSHA, ANSI, EN, and IS (Indian Standards). Certified products have undergone controlled testing and quality checks.

- Supplier Credentials: Confirm that the supplier is registered and compliant with industrial safety norms. Ask for certificates that prove approved manufacturing and quality processes.

- Documentation Support: A reliable supplier will provide clear documentation, including user manuals, inspection protocols, and safety data sheets.

If a supplier cannot provide verifiable certification documents, treat it as a red flag. Non-compliant systems can expose your business to accidents, fines, and project delays.

2. Assess Industry Experience and Focus

Not all suppliers serve high-risk industrial sectors effectively. Look for suppliers who specialize in fall protection for your specific industry.

Ask yourself:

- Has the supplier worked with construction firms, EPC contractors, or industrial plants before?

- Do they understand the safety requirements for roof work, confined space access, or tall structures?

- Can they support project-based bulk orders and customization?

A supplier with industry experience will help you choose the right systems for your work conditions. They can guide you on whether a horizontal lifeline system or a personal fall arrest system is most appropriate for a given task.

3. Evaluate Product Range and Custom Options

Strong suppliers offer a range of fall protection solutions. Your business may need:

- Personal fall arrest systems for individual worker protection

- Fall arrest systems for ladders for maintenance work

- Roof fall arrest systems for builders and inspectors

- Horizontal lifeline systems for large spans like rooftops and mezzanines

- Vertical fall arrest systems for tower and silo access

A supplier with a broad product portfolio can meet multiple safety needs without you managing different vendors. They should also offer customization where systems are tailored to your structure, workflow, or compliance needs.

4. Check References and Past Performance

A reliable fall arrest system supplier should have a track record with businesses like yours.

Gather evidence such as:

- Client case studies showing installations in similar environments

- References from safety managers and safety officers

- Field performance reports from completed projects

Ask potential suppliers for contactable references. Reaching out to companies that have used their systems gives insight into real-world performance, delivery timelines, and support quality.

5. Evaluate Technical Support and After-Sales Service

Fall protection is not a one-time purchase. It requires:

- Installation guidance

- Routine inspections

- Maintenance support

- Training for your team

A reliable supplier offers technical support that helps your safety team implement and sustain safe systems. Evaluate whether the supplier provides:

- On-site inspection and certification support

- Scheduled maintenance checks

- Training sessions for your workforce

- Responsive customer support channels

Without strong after-sales service, even high-quality fall arrest systems can be misused or underutilized.

6. Compare Pricing and Value, Not Just Cost

Price is important, especially for bulk orders. However, focus on value over lowest cost. A cheap supplier might cut corners on critical elements like certification, material strength, or support.

When comparing offers:

- Check if pricing includes shipping, documentation, and basic installation support

- Compare warranty terms

- Evaluate life-cycle costs, including periodic inspections and replacement parts

A higher upfront cost with strong support, documentation, and durability often delivers better long-term outcomes.

7. Confirm Delivery Reliability and Project Support

Timely delivery is crucial, especially for ongoing projects with tight timelines. Confirm:

- Delivery timelines for standard and customized fall arrest systems

- Logistics capacity for bulk orders

- Flexibility to handle urgent requests

Suppliers who can integrate with your project schedule reduce delays and help maintain site safety without interruption.

8. Look for Safety-Focused Communication and Education

A reliable supplier communicates safety clearly. They should:

- Use factual, technical language without misleading claims

- Provide practical guidance for safety teams

- Respond with clarity to technical questions

If the supplier simplifies complex safety topics in a way your team can act on, it reflects expertise and respect for your operational needs.

9. Evaluate Supplier Stability and Reputation

Choosing a partner with operational stability ensures continuity of supply and support. Assess:

- Years in business

- Financial stability and capacity to fulfill large orders

- Reputation in safety communities, trade groups, and industry networks

A stable supplier is better positioned to support your long-term safety strategy.

10. Ask the Right Questions Before You Decide

When engaging a potential supplier, use precise questions with clear expectations. For example:

- Are your fall arrest systems compliant with specific safety standards?

- Can you provide documented performance test results?

- What is included in the standard warranty?

- Do you offer training for installation and inspection?

- How do you support maintenance and periodic checks?

- Can you customize systems for specific structures or projects?

- What are your delivery timelines for bulk orders?

- Do you provide references from customers with similar needs?

Clear questions help you evaluate not just products, but the supplier’s professionalism and commitment.

Case Example: Selecting a Supplier for a Large Industrial Project

A major EPC contractor was constructing a new refinery complex. The project required fall arrest solutions for:

- Elevated tank access

- Structural steel erection

- Confined space entry

- Rooftop HVAC installations

The contractor evaluated multiple suppliers. They shortlisted those with:

- Certified products tested to OSHA and EN standards

- Wide range of fall protection solutions

- Proven experience in industrial safety

- Technical support for installation and worker training

The chosen supplier delivered customized horizontal lifeline systems for rooftops, personal fall arrest systems for maintenance crews, and vertical systems for tower access. On-site training and inspection support enabled smooth deployment and compliance verification. The result was a safer work environment and predictable project execution.

Frequently Asked Questions (FAQs)

What is a reliable fall arrest system supplier?

A reliable supplier delivers certified, tested fall protection systems, provides technical support, and aligns with your project and safety needs.

How do I verify supplier certification?

Request copies of test certificates and compliance documentation from recognized safety standards organizations such as OSHA and EN.

Can suppliers customize fall arrest systems?

Yes, reputable suppliers can design fall protection systems based on your site layout and risk profile.

What support should a supplier provide?

A good supplier offers installation guidance, training, maintenance schedules, and responsive customer support.

Are all fall arrest systems the same?

No. Quality, certification, design, and suitability for specific tasks can vary widely among suppliers.

Should I prioritize cost or quality?

Prioritize quality and compliance. Low-cost systems with poor support can increase operational risk.

How often should fall arrest systems be inspected?

Regular inspections should be part of your safety protocol. Many standards recommend pre-use checks and periodic professional inspections.

Can a supplier train my team?

Yes, many suppliers offer on-site training or certification programs for your safety and operations teams.

What types of industries need fall arrest systems?

Construction, infrastructure, oil and gas, industrial plants, renewable energy, and any sector with elevated work requirements.

Do suppliers handle bulk orders?

Strong suppliers are equipped to handle bulk orders and coordinate logistics for large projects.

Conclusion: Choose Suppliers Who Support Safety and Compliance

Selecting reliable fall arrest system suppliers for your business is a strategic safety decision. It affects worker protection, regulatory compliance, project continuity, and organizational confidence. Evaluate suppliers based on certification, experience, product range, technical support, and delivery reliability.

A partner like Indian Inovatix, a fall arrest system manufacturer and supplier with deep experience in industrial safety, can support your safety officers, project teams, and compliance goals. Our range of fall protection solutions, technical support services, and focus on safety help your business operate with confidence.

Ensure your workplace meets safety expectations. Enquire with trusted fall arrest system suppliers today for pricing, customization, and support tailored to your needs. Your team deserves secure and compliant protection for every high-risk task.