Infrastructure is built with sturdy, dependable materials, and certain types of infrastructure are susceptible to deterioration or damage during construction and throughout their life cycle. High quality Tarpaulins provide protection for all types of construction, including roads, buildings, factories, and bridges. Though they may seem unimportant, they provide an essential component in protecting infrastructure. Whether it is used as a safety mechanism, a durability mechanism, or both, tarpaulin supports construction and maintenance of infrastructure.

What Is Tarpaulin and Why It Matters

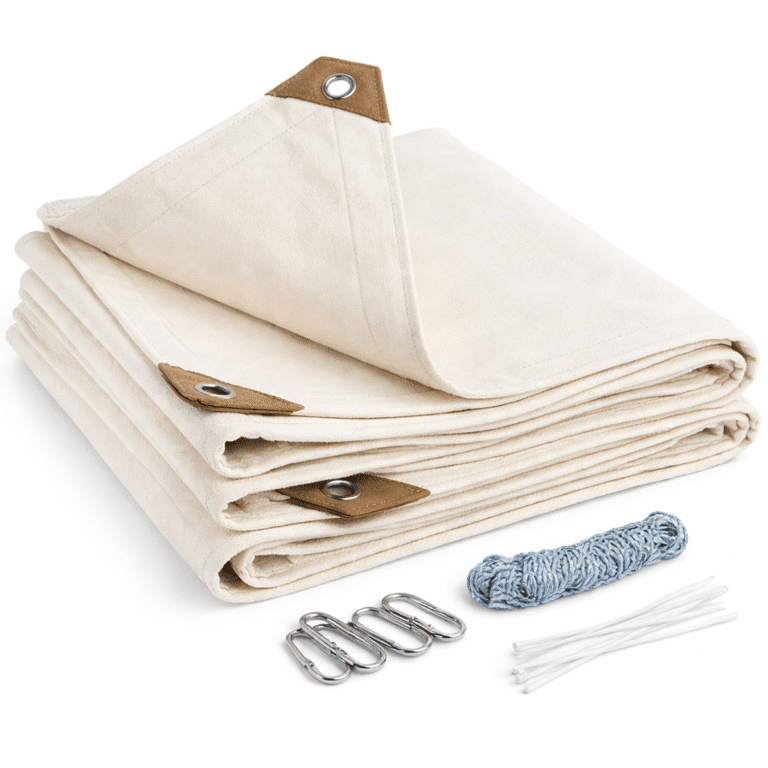

Tarpaulin is a large piece of fabric that is treated to be water resistant, heat resistant, and wind-resistant by being coated with a plastic-like PVC or polyethylene. Because of this coating, it can cover, protect, and secure materials found on a construction site.

Weather plays a large role in causing delays and damage to equipment and materials used on any infrastructure project due to rain, dust, heat, and wind. The use of tarpaulin is one way to mitigate these environmental risks and maintain a steady workflow on infrastructure projects.

Role of Tarpaulin in Construction Projects

Construction sites are busy and exposed places. Materials are stored in open areas. Machines stay outside for long hours. Workers also need safe working conditions.

High-quality tarpaulin protects cement bags, steel rods, wood, and tools. It keeps them dry and clean. When materials stay safe, project costs stay under control. Work quality also improves.

Tarpaulin is also used as temporary roofing. It covers unfinished roofs and walls. This allows work to continue even during bad weather.

Supporting Safety and Worker Protection

Modern infrastructure prioritizes safety; as surfaces can become slippery or construction debris may cause accidents. Tarpaulin helps to reduce these hazards by providing coverage to the earth and preventing water or mud from accumulating, as well as providing temporary side barriers that reduce the amount of dust or debris generated on-site. In addition, some areas utilize tarpaulin as a means of providing privacy, as well as providing wind protection.

By improving the safety of the site, when tarpaulin is in place, it protects workers who are on the site and allows construction companies to comply with safety standards.

Road and Bridge Construction’s importance

The road and bridge construction industry is constantly exposed to the elements, as the materials utilized during the construction of roads and bridges require protection during the setting of concrete and asphalt. As the weather changes, the amount of moisture that is exposed to new concrete and the heat and moisture from the new asphalt can affect the strength of the materials used for the construction of roads and bridges.

Canvas Tarpaulin is placed over the surface of newly placed concrete to control moisture and temperature, thereby increasing the durability and longevity of the product. Additionally, tarpaulin provides protection from the elements for construction equipment that is being utilized in road and bridge construction.

In bridge work, tarps are frequently hung below the bridge deck to catch rocks and other debris prior to being.

Use in Industrial and Factory Infrastructure

Factories and industrial buildings use tarpaulin in many smart ways. During installation or repair, machines need cover. Tarpaulin prevents dust and moisture from entering sensitive equipment.

It is also used to divide large spaces. Temporary walls made from tarpaulin help manage workflow. This is helpful during expansion or maintenance work.

Warehouses use tarpaulin covers to protect stored goods. This keeps products safe and reduces losses.

Environmental and Cost Benefits

Quality tarpaulins contribute to sustainable practices. Protecting materials diminishes waste, which leads to fewer damaged materials requiring replacement. As a result, financial savings and fewer resource expenditures occur.

Additionally, reusable tarpaulins provide long-term cost savings. Large cover structures are constructed as needed and can be moved and reused for temporary projects.

Modern tarpaulins can also be recycled, making them a better choice when planning eco-friendly infrastructure.

Selecting the Right Quality Tarpaulin

Not all tarpaulins are created equal. While a project’s infrastructure must have a solid foundation, it must also be built using high-quality, thoroughly tested materials. High-quality tarpaulins have durable coatings (to protect against water and UV rays), heavy-duty stitching, and are made of heavy-weight fabric.

Because of the nature of the industry, low-quality sheets will fail rapidly, thereby increasing the chances of an accident or injury. To determine what type of tarpaulin to use, experts recommend selecting one according to a project’s size, the conditions under which it will be used, and the type of loads it must bear.

Choosing the appropriate type of tarpaulin is an indication of professional planning and technical competence.

Conclusion

High-quality tarpaulin is more than a simple cover. It is a strong support system for modern infrastructure. It protects materials, improves safety, saves costs, and supports sustainable practices.

Its role is based on real experience and proven results. That is why engineers and builders trust it. As infrastructure continues to grow, tarpaulin will remain an essential tool behind the scenes.

Also Read: https://www.youthfulyarn.com/